Welding a pipe fence is fairly uncomplicated but getting the pipe fence saddles cut and prepared CAN be a time-consuming process. Almost anyone who has welded a pipe fence will tell you that the biggest hassle is cutting and coping the saddle to get a good fit.

The First Step for Pipe Fence Saddles

If you have never welded a pipe fence before, I want to explain the different processes of making a pipe fence saddle. Some folks use a paper or metal saddle template, which they then trace onto the pipe with soapstone, chalk, or marker. To create the saddle, a welder then uses a handheld torch while slowly and steadily rotating the pipe to make the cut. They MUST keep the pipe at a uniform angle to ensure precision. A more experienced welder can use a chop saw to notch the pipe to a crude V shape.

The SRFB saddles connect to the post and you weld the rail in place.

Grinding a Good Pipe Fence Saddle

Cuts made by hand have a tendency to be irregular. In order to ensure a secure rail to post fit, there will be grinding involved to shape the saddle. This is where your guesswork comes in… there is a lot of grinding and refitting… and then regrinding. If you are utilizing used oilfield pipe there is a high probability of ending up with a rail that is too short. You could weld “extra length” back on to make up the deficit; or just scrap the pipe and start all over.

Not to mention, even after the pipe is saddled, the welder may not be done. Torching can change the pipe’s properties and it leaves behind slag; both resulting in poor welds, increased expenses, and additional time. The welder may also have pipe that has become magnetized.

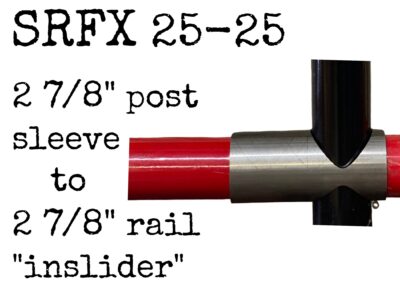

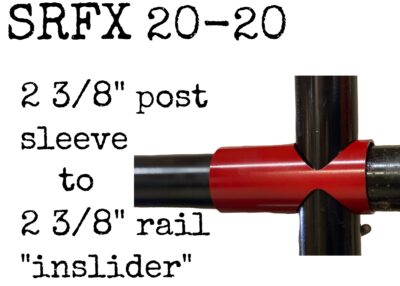

The SRFX saddle slides over the post and sets 2 rails in place (creating what we call an “inslider”).

The Time Saver

Make it Simple, But Significant.

Don Draper

Saddled ‘N’ Ready has taken the guesswork out of grinding and torching your own pipe fence saddles:

- Numerous steps are eliminated that reduce the time needed to create saddles

- There is no open flame which makes them safer to use in the field.

- Your weld is not corrupted by the dust and debris generated by grinding

- The composition of the pipe is not altered

- Magnetized pipe can STILL be used

- One person can do an entire pipe fence

- Saddled ‘N’ Ready saddles are versatile and can also be used for corrals, H-Braces, lean tos, sheds, and more!

Just Set. Weld. And GO!

-

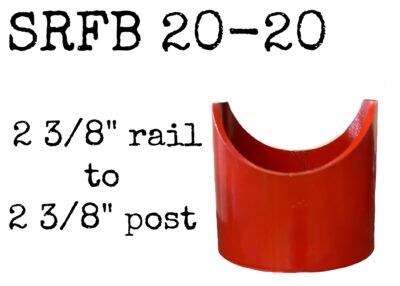

SRFB 20-20$6.00

SRFB 20-20$6.00 -

SRFB 25-25$6.00

SRFB 25-25$6.00 -

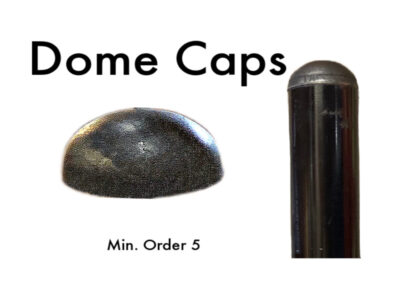

SNRC$2.00 – $2.75

SNRC$2.00 – $2.75 -

SRFB 20-25$6.00

SRFB 20-25$6.00 -

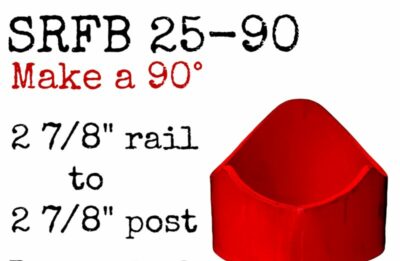

SRFB 25-91$6.00

SRFB 25-91$6.00 -

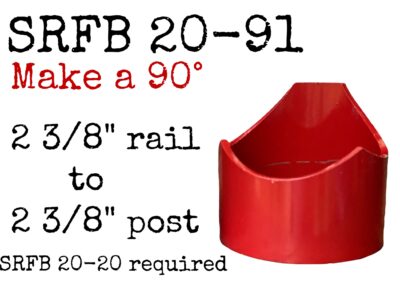

SRFB 20-91$6.00

SRFB 20-91$6.00 -

SRFX 25-25$10.00

SRFX 25-25$10.00 -

SRFX 20-20$10.00

SRFX 20-20$10.00 -

SRFB 29-25$6.00

SRFB 29-25$6.00

Love the product, Huge timesaver.

Looking for 2 7/8 rail to 2 3/8 post. Not building fence but corral panels and bottom rail is 2 7/8 with 2 3/8 post that come off of it.

If you don’t have it how hard is it to have some made from your manufacturer?

Sorry, I just found message. Yes, I have a product. 903-570-8228, Feel free to call

Thanks Mark